Did the top cover had any thermal path from inside above the processor when you opened it ?

Is the Infrared projector closed or open ?

I wish you made a pic to show the inside .

That was a brave move , I wonder if the infrared projector is open or not , because if it is open then dust particle going to accumulate one way or another and interfere with the scanning .

I had one small dust particle on my MINI blue light projector since we have no glass protection over the sensors and a black line showed on the projected pattern , but got it cleaned out .

Hi, I am not sure how the misunderstanding is caused. Now we only have the info about our dual-axis turntable as below:

360° horizontal, ±30° vertical, no blind spot scanning

Bluetooth connectivity, easy to control

Controlled rotation path, flexible to various objects

The dual-axis turntable A230 is a tailor-made accessory for Revopoint scanners. It adopts the design of 360° horizontal, ±30° vertical, and a controlled rotation path for fast point cloud data acquisition. It solves any previous issues of incomplete data acquisition or holes caused by improper operations such as ambient occlusion, which greatly improves the scanning quality and efficiency.

Sorry for the inconvenience.

Will Revo Scan be able to control the turntable, including automatically reversing direction and pausing to reacquire tracking?

@JeffLindstrom wishful thinking ![]()

Hi Selina , the measurements was probably from the MINI Standard Package turntable ( and POP2) what are exactly that and not the Dual Axis Turntable .

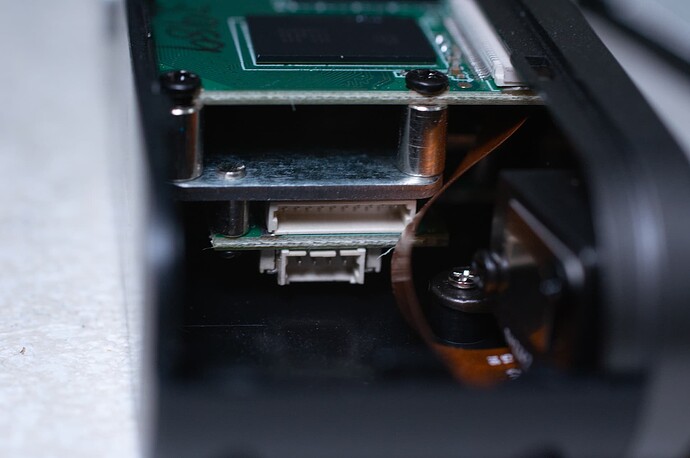

@cellmon can you scan the scanner “lid”? And if you have another scanner, maybe top of the circuit board. I think it would be super cool to 3d print a new top with a cutout for an Arduino CPU style heatsink. This would keep the dust ingress to a minimum but allow all the heat to escape.

BTW, that looks like a pretty tricked out scanner rig you have!

Bruce

This technology already exists on a competitor’s platform and it would be trivially simple to implement, seeing as how Revo Scan already detects when tracking is lost.

Of course it exist since I used it 22 years ago and I paid $5000 for the turntable and software , I never said it don’t , but as you see a turntable like that cost today $700 and a software even more . It can be all done , the question is , will it be done ?.. maybe with the time but not soon enough .

Automatic turntables do not use full rotations and capture the model by single frames in 30 degrees distances , and fuse it each time before next capture.

MINI or POP scanning with single frames do not works well as it introduce too much noises , it needs the rotation to proper capture the model in 3D space and align the frames for noiseless perfection.

I tried already everything .

It will be up to Revopoint to rewrite the software but it may be not as easy task as POP and MINI are portable 3D scanners and not stationery , automatic turntables need the scanner to be in exact position and angle each time for the process.

That seems counterintuitive. The Revopoint turntable advertises Bluetooth, so it’s going to connect to something and what, if not Revo Scan? Revo Scan already detects loss of tracking, so it seems (to me, at least) that it would not be difficult to tie the tracking loss detection circuit to the motor control functionality that the Bluetooth-enabled turntable already has (or at least should have).

I am expecting an app for controlling the turntable as many others have . If they add that function to the software, then it would be perfect . I just lower my expectations , as I don’t want to be disappointed or post misinformation to people based on pure speculations and misleading them .

The turntable is not yet in production or any samples done so I would wait for the proper specifications first , because right now all we do is speculate about and that are no facts .

That is all about .

I don’t know if the heat will destroy it first, or if it will be destroyed by modifications, or…

Since I don’t own any other high-resolution scanner, I’ll attempt to scan it with photogrammetry!

@cellmon thanks for the pictures , there is so much room for improvement and for proper cooling . Now I can see clear why my aluminum heat sinks working so well .

I had some conversations with Attblime NYC, they sent me some extra stuff and promotional new markers to use with MINI, not yet online in usa , the ATTBLIME AB2 Scanning Spray is fantastic (Sublimation 2 to 4 Hours) . I made tests with both AESUB Blue and Attblime AB2 and the results was great when using with MINI , half the price, stays on for 2 hours compared to Aesub blue less than 1h , actually 30 min with warm weather .

The surface was so fine with AB2 , it did not clogged. the details even when using can spray with the additional head spray nozzle they including . Super product .

Beside the can format also got the 1L can to use with my airbrush and 0.7mm nozzle for very fine applications .

I guess I have my new favorite 3D spray for fine applications .

Any time frame on availability?

Not yet Jeff , from what they said they just opened the new online store here on east coast , still putting everything together .

Everything else is available in Europe and UK .

I am going to test out the markers today and see how MINI friendly they are in practice.

More information will come out in the near future. ![]()

Can you give me the link to your light box please? What you are doing with this scanner is inspiring! You are helping so many people with a product that is better than most users are capable of using. My hat is off to you for your time and efforts on the pop2 thanks!