thanks fot this explaination, this helps people making the good choices!

Bruce , if I find one in my change I will try using my Homemade Zinc Oxide spray and test again.

the best results with current resolution so far are for Depth relief at least at 0.50mm - 0.20mm, it can scan lower , but lower relief are not so spectacular .

The final version would be much better of course so right now I can only tell you how my sample is working for me at this moment .

The MINI can also scan in Dark mode (during which, it isn’t bothered too much by lighter surfaces being over-exposed).

Ah forgot the Dark mode , thanks Jeff !

Yes I did , it works as I mentioned early above . However there are no new features for POP2 if you asking , the POP2 features are right now at max , any higher pitch point values would generate too many noises . However the CPU is now on the quiet side.

That’s great that you got a MINI to test. Because I’m most interested in Reverse Engineering I would like to see you do some quantitative tests (Working Volumes/Stand-offs, Accuracy, & Resolution). I’m most interested in it’s Resolution. You can get an inexpensive Thread gage on Amazon for $10.

In the examples below, One is my POP and one is from an old Faro Arm Laser Scanner. It would be nice to see the POP2 and MINI results.

@nafis

Chris , we all need the proper volume , accuracy and resolution , no matter it is for Reverse engineering or dental modeling or whatever , it is as much important for my work as it is in yours . I just don’t share my work as things are confidential .

So lets do it , however right now the specifications of my device and software are at maximum , because I am using only a prototype, no RGB , no frontal filters and all sensors are exposed and fragile, I also can’t yet calibrate or see calibration results , so I hope things gonna definitely improve and change with the final build for even better results. Just so you know

P.S I ordered the Thread Gage , it will be here on Friday .

It will be interesting to see what the smallest thread size the MINI can resolve. In my example I used the metric 1.25 to 6.0 range. I measured the gage thickness to be 0.41mm with a caliper. So the MINI should easily be able to measure the steps.

Definitely , it can go much below that , the pitch point resolution is pretty good , the best resolution showing at distance of 100mm from the object .

My MINI premiere video and showcase will be on my channel on May 30

stay tuned ! and thanks for the support !

That looks very good Chris , but can be better , I am going to use my Zinc Oxide spray for this test tomorrow , AESUB Blue spray seems to be little to thick on the fine edges , the orange one works slightly better but still clogging and rounding the fine details . There should be no noises at this level but I guess it was from the spray and too high gain .

I need to think about a cover for the sensors for my prototype, maybe fine glass screen protector will works , because a single dust particle can already change the blue light projector pattern. You can actually see it on the model projected as black line . I am using my airbrush compressed air to clean it each time because you can’t touch the sensors fine lenses as it can alter the calibration .

Since the MINI did so well, I would also do a scan of the Thread gages from 0.25 - 1.0mm. We want to find the gage size that we can no longer discern the teeth. Do you have any other 3D Scanners in your arsenal that you could also do the tests with? I hear my Lizard should show up in a week or two. I’m expecting it to have results between the POP and POP2. I have to run my suite of tests on it.

Yes I have Chris, but the quality is below MINI , I will try to see if there are any significant differences.

Definitely , I know for a fact that MIINI can pick up details at 0.3mm , 0.1mm is where it stops but you can’t see that level with your naked eye either.

Some new scans with MINI

It is low version at 50K

I obtained same results, and even more in the small size of the gage, i just don’t know how to color them like this ![]()

Just post a scan pic. I got the colors by best-fitting a plane to the first gage. Then compared the scan data to this plane. I used a caliper to measure the gage thickness and got 0.41mm.

The gage did not arrived today, have to wait until tomorrow ![]() frustrating …

frustrating …

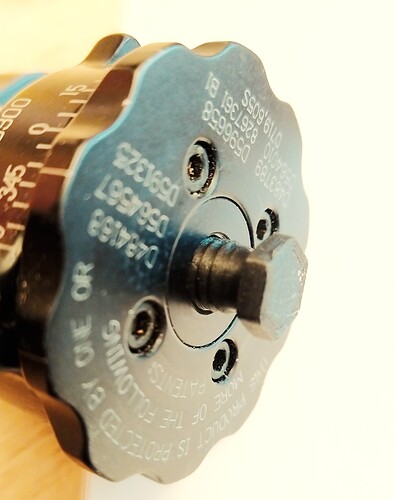

so I checked something else and scanned Screw adapter 1.4" - 3/8" thread and printed out to see if it works , just to make a point , and it did , beautiful clean scan .

3D Printed Screw adapter thread 1/4"

3D Printed Screw adapter thread 3/8"

Really amazing how accurate it was to just throw it on the printer and boom, you have it! I am pretty impressed with this!