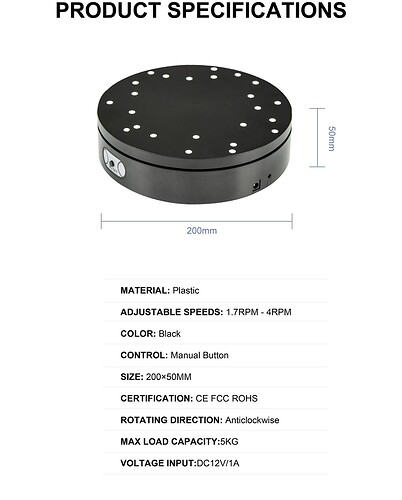

This actually upsets me also as EVERYTHING states it is an adjustable speed turntable, even your own website. ADJUSTABLE SPEEDS: 1.7RPM - 4RPM - this is a link to your picture on your website at this very minute. If it doesnt show up properly I will also add a jpg. First one is your website and second is the jpg of it.

The LED next to the power jack, that looks like an Infra Red diode?

The BKL Turntable shop sells lots of different types of turntables, where for many of them an IR-remote is included. Maybe that is a way to get speeds programmed?

(The one that Revopoint is including in the shipments, is not listed there)

Hi @KnightRid Sorry, it’s really our fault. The description is wrong. We will revise it as soon as possible.

Well, updating the website is obviously not what people want, they want a turntable with adjustable speed since that was what was supposed to be coming based off of EVERYTHING that was put out about the turntable.

Especially knowing that a tester is already having a problem with it turning too fast for good scanning, that should tell you that this is just the beginning of the complaints if you go forward shipping turntables that don’t have speed control.

Hi @Zoltan3D After discussing with our product team, they said that the algorithm of POP does not require high-end computer. Under normal condition, insufficient power supply may often cause losing track.

Under such condition, is it possible for you to give us the computer configuration of the two computers, so that we can retest the product to analyse the properly real reason?

Besides, we will highly appreciate if you can send a video about the turntable speed and your scanning process to us.

Thanks again.

Hi @Mr_Hankbot, thanks for your reply. We can understand your concern, and we sincerely hope you can give us some time to analyse the problem. Because our product team tested and adjusted the speed of turntable many times, usually it won’t effect the good scanning result. You can see our videos on Youtube, and also many users shared their nice scanning result in this forum and also Facebook group.

We do value every user’s feedback, so we will also contact the factory to see the possible solution if the turntable speed is really fast to effect the good scanning result. Thanks again.

I would appreciate if your team at least could suggest a compatible board (e.g. from aliexpress) we could add to existing one to add speed control.

What really seems easiest to me, if the idea is to ‘upgrade’ the existing turntable, would be a simple stepper motor controller (https://www.seeedstudio.com/Stepper-Motor-Driver-p-4551.html) this one works well with that motor, a controller (any programmable one, I would use an Arduino as I have a spare one around), a potentiometer as an input signal (Arduino - Potentiometer), and some code to convert the potentiometer value to a speed (would have to search for some code samples there)

I am working on it, the code are ready for my arduino, I just waiting a new arduino nano because I used all of them for various projects

Because after all its a simple stepper motor what you find in all arduino kit

Good

That said, as I didn’t get my unit yet, what kind of ‘switch’ is it that they use ? A simple button (boutton pression) or a real switch (interrupteur) ?

In the first case it would even be simpler to use the integrated button to navigate through a series of predefined speeds instead of adding a potentiometer, less intrusive

A simple push button, but it takes 10 sec to make a hole and add a

potentiometer

If it’s a simple button, I think that’s the way I’ll go  , the less there is to change on the hardware, the better, and I think that if others are interested in ‘upgrading’ but have little knowledge it will be simpler to do (and less parts to buy). Toggling between 3 to 5 different speeds through the push of a button seems ideal to me (but less flexible I do admit). So you’ll do the pot version and I’ll do the button version

, the less there is to change on the hardware, the better, and I think that if others are interested in ‘upgrading’ but have little knowledge it will be simpler to do (and less parts to buy). Toggling between 3 to 5 different speeds through the push of a button seems ideal to me (but less flexible I do admit). So you’ll do the pot version and I’ll do the button version  (provided that I get my POP soon

(provided that I get my POP soon  )

)

but it would great for revopoint to test a compatible part first and then let us know which on is it to buy.

I think 1.0 rpm or even bit slower would be the best to not lose tracking.

The stepper controller in the link is made for this motor (seeedstudio sells it as a kit together), and for the board, really, it’s a simple matter; Arduino Uno can be powered with 12v, so 1x Board, 1x Stepper controller and a few cables (and code). Maybe a 3D printed case to hold it, but if you use it with the integrated motor and button, that’s really all, but I let anyone comment, maybe someone has a better idea

thx! I wouldn’t mind you to build and test it first

I understand, and honestly I would love to  . I ordered the stepper controller today ($3.80), hoping that meanwhile I get my POP with the turntable; It may well be done by someone else before who already received his unit and is working on it, but promised, I’ll get my hands on it as soon as possible, and share experience. I already had plans to create my own turntable for photogrammetry but seeing this simple and easily hackable turntable I’ll use it as a base

. I ordered the stepper controller today ($3.80), hoping that meanwhile I get my POP with the turntable; It may well be done by someone else before who already received his unit and is working on it, but promised, I’ll get my hands on it as soon as possible, and share experience. I already had plans to create my own turntable for photogrammetry but seeing this simple and easily hackable turntable I’ll use it as a base

cool! i wish you get your POP very soon!

I am looking, if any possible, for a solution of altering the existing board, for example with arduino uno, but without any soldeting. do you think this is possible? and if so, any ideas/suggestions which additional cables to order to avoid soldering? thx in advance!

Is it cheaper to upgrade it or just buy another one like this - https://www.amazon.com/Rotating-Motorized-Turntable-Photography-Products/dp/B08HD9SQZK - in the USA that one is $40 and has variable speed, tilt and batteries or power cable or rechargeable batteries.

In fact it should be possible without soldering I believe, you’d need ‘jumper wires’ for that, Male/Male & Male/Female, there are plenty of places to find those, depending on your country

I bought a small turntable today (diameter 25cm) for manual spinning and hope to get it soon. I have to check first the ideal speed for scanning, and if it works fine I even might stick to manual spinning.