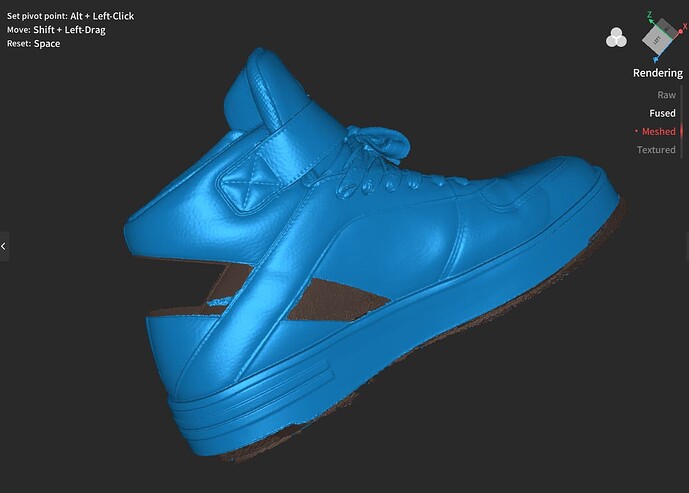

I tried more and this was the best scan I could capture, but I hate the surface roughness in these last pictures. Surely, these irregularities occur somewhere, and the beautiful parts that I scanned so much turn into garbage thanks to these irregularities. hours of work and waste of time

Next step would be to learn about the key frame edit mode where you can try to remove the frames that are causing you a problem. Warning about key frame edit mode: all changes are permanent, and changes are periodically saved without your intervention while you are in that mode so always backup the project first.

I also like standard mode fusion a lot of the time when I have to merge pieces. It seems to lack some of the artifacts that advanced can give you (but it will make for a fuzzier looking point cloud until you mesh it).

I cannot add much more to this conversation.

-Small details will never be enough for tracking because the scanner does not use all the points of the frames to track, but only a small percentage evenly spaced out, so small details will not be prevelant.

-You start your scanning back up from an uncertain and tricky area and leave room for misalignment to happen right when you press continue.

-You often position your scanner in a way that it can barely see the subject, and let misaignment happen right there.

I admit, scanning a shoe in feature tracking mode might not be the easiest thing ever. You should scan these with markers attached to them. That way, the software will immediately tell you that it cannot track the object before any misalignment happens in the data.

I make separate scans for the roughness on the top and side. And I want to combine them, but when I delete a single surface, such pieces remain inside. These are driving me crazy, how do I delete them, this is what I am trying to tell you, we cannot scan the product perfectly in one go, I want to scan them separately and I want to combine them. Either it cannot be combined properly or there are pieces left inside, and sometimes it cannot be integrated one on top of the other and creates irregularities. So, I cannot perform a proper scanning process at all.

And this is another problem. Can you watch the video below? I want to clean the pieces I scanned piece by piece before combining them, and then I want to combine them, but after cleaning, the Uncleaned version appears in the “MERGE” section. I overwrite it again and it brings back the areas I cleaned, so this does not work at all.

What I have been trying to tell you for a few days is that when I try to scan this product on the table by changing the direction at a time, there are slips and roughness. I want to scan the product more than once and combine the clean areas, but this time, as you see in the video, problems occur and when I combine the clean areas, I still get problems at the points. There is slippage and this causes glitches, so I cannot get a smooth scan output at all.

Here are the wonderful results of the wonderful Revo Scan software. Now, am I to blame? I try every method, but the result is obvious.

When you’re cleaning the scan with the lasso, etc, be aware that you want to be in the Fused display not the Meshed. I’d guess you’re cleaning the mesh instead of the fused cloud.

Merging from multiple scans will create seam lines because of the noisy data at the edges and also because the inaccuracies in the scan data itself, thats how the software is right now, they are working on it. You can trim off the noisy edges manually (as you did) before merging them, this would be an important step to achieve clean scans. As for why theres overlap problems, I cannot tell unless I watched how you scan in person. The reason might be as simple as you just grab the shoe too hard and you change its shape between scans, cannot tell. It can also be that there are many small slips occuring during scanning because the surface barely has enough features. Thats why I suggest marker tracking instead. That would solve a good bunch of your problems and you could easily do the scan in one go.

Here is my hiking boot scan source files, you can watch the scan process by the key frame edit feature, it might give you hints.

(link deleted)

Thank you for your answer, friend. I did it as you said and cleaned it, but the merging problem still persists. I even isolated and overlapped more than once and when I try to MERGE again, they still overlap each other. And I cannot get a smooth surface. I try to explain this to my friend, but he does not understand me at all. If I cannot scan the object properly at once, I try to scan it more than once and add them one on top of the other, but the software does not succeed either way. But the friend insistently refuses to accept this. So, I am trying to send you samples with photos by making a video. What more can I do?

Actually, I will combine them, as I showed in the 2 scans, the surfaces are smooth and problem-free. But when I combine them, they form layers on top of each other and become rough. I also showed you the version before combining them in detail.

I’m shooting a second video for you. In this one, I give up on the details and do the smoot process multiple times, then I want to combine it with the other one again and look, this time I get worse surfaces on the other side of the shoe, so what I want to tell you is that there is no method I haven’t tried, but I can’t get a proper scanning result.

Looks like you used simplify on one of those shoe scans. Honestly I don’t use anything other than isolation and overlap on the point clouds.

Did you have to move the shoe at all between scans? I doubt it holds its form exactly.

Really you’re not too far off. Try standard fusion. Look into key frame editing to get rid of bad frames. Continue to learn how the scanner and software behave.

Ok, I keep trying and finally I got a good scan result. Of course, I also have shortcomings and there are things I don’t know. I constantly try different things to learn them and I write to you here. Don’t worry, I am trying to implement your recommendations.

I finally managed to scan this piece that I couldn’t scan, so I chose to scan this painting by hand. It was beneficial to use this table, especially when scanning. This way, I was able to scan the groove part and other sides more easily. Then I assembled the neat pieces. I made minor corrections with meshmixer to make the surface smoother. I will share the result when I get it printed. Thank you for helping anyway.

It seems you are doing things to intentionally try to make scans fail. The shoe was scanning fine and you stopped the scan, moved the shoe, and then tried to keep scanning. Why did you do this? Why not let the shoe finish its revolution. Rescanning over the same areas does not lead to a better scan and can confuse the software as you have seen. If you are going to stop and reposition, make them two different scans and merge them.

Like others have said, you should be using markers, either on the parts or use the marked drop cloth. Same thing goes for the heart. Too many large flat surfaces and not enough feature to be able to use feature mode. And again, you are moving parts mid scan. When you angle the part with the red cap and scan again, it does a really good job for the first revolution. Then you start re-scanning areas you’ve scanned already and start having problems. Scan one revolution and then stop. Reposition part, start a new scan and do one scan revolution and then stop.

3d scanning is a skill that takes time to develop. Plenty of people are able to generate good scans using the same software and hardware. 80% of the time issues are going to be user error or skill issues. LISTEN to what others in here are suggesting and try implementing thier comments. Just complaining and posting videos of you doing the same things over and over isnt going to help you get better at scanning.

Friends, I continue my scanning practices. But there is another problem I encounter.

The surface looks smooth as you see in the pictures. This is a lamp on button. But when I want to print, errors like this appear.

I cannot delete some point clouds in the scan data. The point clouds that I marked like this are formed in the background. These cannot be cleared completely and the point clouds in the front (which should not be deleted) that I want to delete are also deleted.

Combined with properly scanned data, I get a result like this

Hi

I think you could simply smooth those parts after meshing, either directly in revo scan or e.g. meshmixer.

I am only seeing cleaned up models of the front side. Let see the cleaned up mesh of the backside before you merge them. Its looks like the back side is putting points over your cleaned up front side and that is resulting in a bad file for 3d printing.

Hello again friends. I now own a dual axis turntable. I know a song like this, I’m sending you a video. In your opinion, where am I making a mistake that creates such roughness around these edges?

Hi @ercan_wrc

This don’t looks right , you should have smooth surface .

Try to not over scan the same angle more than once , around 400 frames max , don’t move the scanner down or it can’t register markers , just finish one rotation at 45 degrees angle and if not complete scan the other angle after .

Before merging you need to clean the scan from overlapped points and lose point and trim rough edges of both scans .

After merging you need to clean it again from overlapped points what results from merging .

And most important don’t use the slider to the max when fusing using Advanced mode , you can use 0.1 for that type of objects .

Using too high fusing settings will result in artificial noises that are hard to clean . Less is better .

And most important avoid any yellow colored and it bright light , set the Exposure to Auto so it can adjust itself if needed .

And the last thing , if you have issues with tracking scanning small objects try to calibrate your device with good lighting .

I can scan coins with Mini 2 and have perfect details and smoothness, so if you have any noises try the followed steps from above . It will works .

And please never slide everything to maximum , especially not when meshing your scans , you need to pay attention to the Grid settings as it correspond with the fusing settings .

For example if you fused at 0.1 your meshing Grid should be also 0.1 not lower or higher for best results and details .

But first you need to have perfect point cloud so old try again 360-400 frames max per rotation .

Let me know how it worked for you .

Almost a year later, I have purchased a mini 2 and having similar issues.

Will try these settings. I posted here:

Brush tool and smoothing in Revo Point 5.5.3 - Support & Feedback - Revopoint 3D