Hello everyone!

If you like my showcases, you can support me and buy Mini 2 by the links below:https://bit.ly/4bg9Kir https://bit.ly/4bdH9uc

I want to start with an easily recognizable thing - it is airpods.

It is 5.75mm.

Here you can see a 3D-scanned with MINI 2 Model:

And here i checked this dimension in software:

WOW! It’s 5.7573!

Now i am hesitate, what tool is more accurate, my 0.05mm graded caliper or a MINI2 with it’s 0.02 single shot precision?

2 Likes

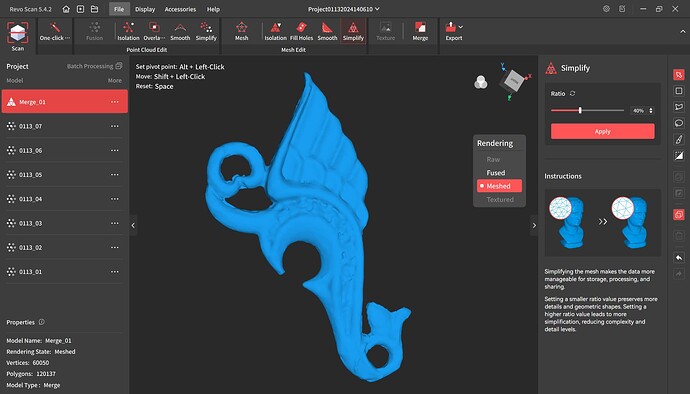

The next one is a pendant in the shape of a dragon wing.

I did make two scans and then, i combined them in Revo Scan 5.4.2 software

Then i made a mesh model

And cleaned up in Meshmixer

Here you can see a dimensions measured by a caliper and in a software:

This model could be used for 3D-printing in a castable resin.

1 Like

Logitech Pebble M350 Casing.

Mouse width measured by a caliper is 58.85mm

3D-Models.

Top part:

After scanning process and merging, i cleaned models in the Meshmixer.

Now, we are ready to make a measurements:

Model width was measured in meshmixer and it is 58.85752mm.

It differ from a caliper value by 58.85752-58.85 = 0.00752mm

2 Likes

3D Scanning an assembly of a lego gears.

Here is a model:

1 Like

Here is a black object. It is a tire from a toy car.

The result:

1 Like

This is a drone Impeller. It is tiny and it has a complex surface. Lets scan it!

I made a two different scans and merged them by points in a Revo Scan software.

Here is a model.

Reverse engineering:

And the last - it is recreation in a nylon like resin on mSLA 3D-printer:

2 Likes

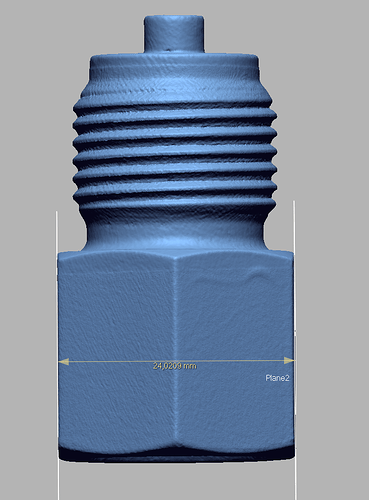

The next one scan - it is a 3/4 adapter for a manometer.

I measured a 24.05mm distance with a caliper.

Here is a scanning process:

I made two scans and merged them:

Look at this! It captured an inner surface very well!

And here are dimensions measured in the software:

24.05mm was measured by a caliper

If you impressed with the MINI 2 accuracy, you could buy it here:https://bit.ly/4bg9Kir https://bit.ly/4bdH9uc

2 Likes

3D-Scanning and 3D printing a door keys.

The result:

I recreated them in a nylon like resin on a mSLA 3D printer:

And yeah, they are able to open a door!

2 Likes

Using MINI 2 for reverse engineering a small gear for a rare actuator.

Measuring of the shaft with a caliper:

It is between 2.1 and 2.15mm.

I made two models and merged them in a Revo Scan 5.4.2

The result:

Measuring a shaft in a software:

It is 2.116mm.

Reverse engineered model:

3D printed in a nylon like resin:

Installed into a reductor:

Dimension accuracy is perfect!

2 Likes

3D Scanning a skull from a medical university.

To be or not to be that is the question!

I put it on a transparent holder that is invisible for a 3D-scanner.

Most difficult part of a scanning was to get a perfect scanning distance. Most of the time i hold scanner manually and tried to reach “excellent” zone.

And here are the results.

Upper jaw and teeth:

3 Likes

Here is a synthes medical gearbox housing.

I put a mating spray on it (IPA+powder).

3D-scanning in a feature mode:

As you can see, there is only a small amount of powder on a model surface. But, mini 2 is able to capture details without a problems.

The result:

As you can see, MINI 2 was able to capture a thread:

And here are dimension comparisons.

Measured by a caliper:

Width = 26.9mm

Measured in a software:

Width = 26.9008mm

Difference = 26.9008-26.9 = 0.008mm!!!

Measured by a caliper:

Diameter is 7.9mm

Measured in a software:

Diameter is 7,845mm

Difference = 7.9-7.845 = 0,055mm!!!

This is really amazing accuracy!

If you like my showcases, you can support me and buy Mini 2 by the links below:https://bit.ly/4bg9Kir https://bit.ly/4bdH9uc

4 Likes

Gary

January 29, 2024, 2:40pm

14

Incredible results, just what you need when working with small objects.

How are the initial fused point clouds coming out? Are they relatively clean or do they require some work?

1 Like

Thanks! It strongly depends on distance and model shape. On my opinion, point clouds are much cleaner than what i got with mini-1. So, yes, models are relatively clean.

1 Like

Man, I take a week off to be sick, and come back to see this showcase blowing my mind.

These are incredible scans, man. Fantastic work!

1 Like

Thank you! I tried to do my best!

Hello everyone!

Here is a 3d-scanning process video https://youtube.com/shorts/zB1kuhli7hY?feature=share

If you like the result, you can buy mini-2 here:https://bit.ly/4bg9Kir https://bit.ly/4bdH9uc

4 Likes

Yuki30

August 14, 2024, 9:01am

19

Thank you for sharing it!The results looks great!