My name is Federico, i’m an assistant professor at the university of Genoa, where i teach advanced 3D modeling with CAD softwares, during the year the students will learn to use of 3D softwares and 3D printers as well;

My goal is to introduce them also to the 3D scanning world,

I have worked for a company that deal with high level 3D scanners at metrology grade;

I could use high level 3D scanners to teach my students how it works, but they are expensive, my dream is that showing them the technology and its advantages, the students would dream to have one, with the accessible price of the Revopoint 3D scanners they can buy one easily,

I think ‘‘trying’’ and ‘‘doing’’ is the best way to learn!!

In the past few months i had the opportunity to try the Revopoint MINI, the POP2 and i personally backed on kickstarter the revopoint RANGE,

let me say they are amazing!

-

With the revopoint MINI i can 3D scan every small detail, but it suffer at big objects,

-

With the RANGE i can easily 3D scan big object but the level of detail is not even close to the mini,

-

With the POP2 we have a good compromise, but with the MIRACO we are at another level!

If i will have the possibility to became a beta tester i will use the MIRACO to teach my students, letting them try and discover the huge possibilities of that technology!

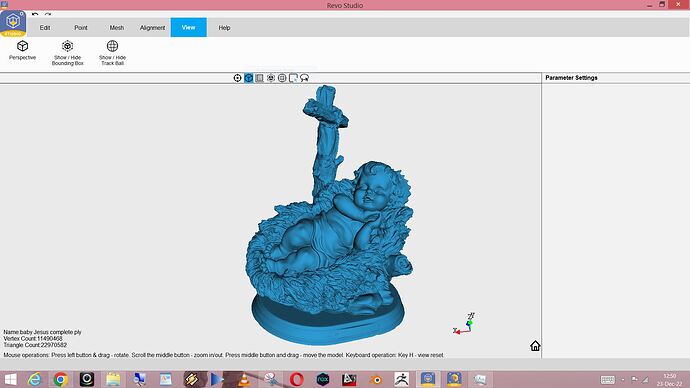

the following Pictures show some of the objects that i 3D scanned with the Revopoint MINI, POP2 and RANGE

With the mini i 3D scanned a component of the wheel of a prototype McLaren, i did the Reverse Engineering and optimezed the shape with CAD software and validate it with FEM and Dimensional analisys softwares

With the Revopoint RANGE i 3D scanned the car body of the McLaren Prototype

With the Revopoint POP2 i 3D scanned all the interno front components under the front car body:

All the components that i 3D scanned are of the same Car, i needed to use 3 different revopoint scanners to achieve these amazing results! but with the MIRACO i could do everything with just one and i think it is a game changer and i really would like to test it out!!

Best Regards

Federico