Dear Revopoint community members,

Thank you all for your participation! After careful consideration, we have decided to select @Pewcannon as MIRACO’s beta tester.

Once again, we appreciate everyone’s active participation. If you weren’t selected this time, please don’t be discouraged, as your participation is still under consideration for future opportunities. Please keep an eye out for updates from us.

Please DM us your address information so we can arrange the delivery of the MIRACO. @Pewcannon

Best regards,

The Revopoint Team

—————————————————————————————————————————————

Hello Revopoint Community!

As a company dedicated to enhancing product performance and meeting diverse user needs, we are beyond excited to announce the launch of our flagship 3D scanner, the MIRACO!

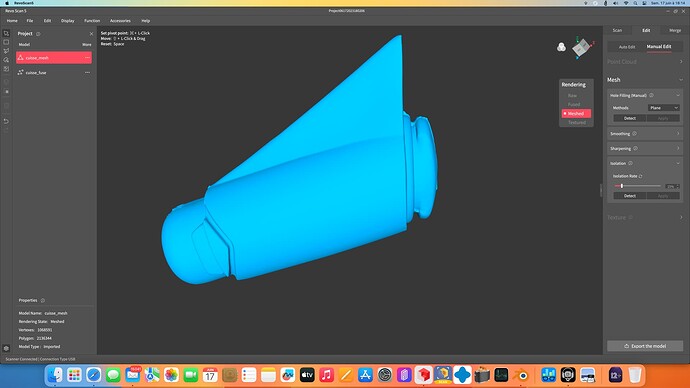

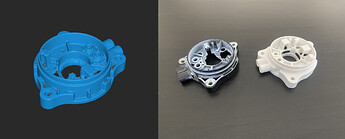

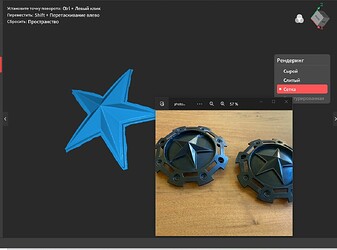

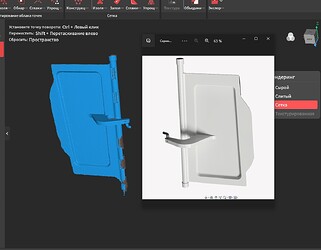

From bolts to helicopters, the Revopoint MIRACO can 3D scan it all. This lightweight standalone scanner is packed with advanced hardware, enabling it to accurately capture big and small objects on the fly. With its massive 48-megapixel RGB Camera, users can experience photo-realistic 3D color models.

Learn more and sign up here: Revopoint MIRACO 3D Scanner Kickstarter Sign Up

We’re recruiting for a Beta Tester who will get to experience MIRACO before anyone else and, most importantly, get MIRACO for free.

To participate:

![]() Click the link to subscribe it: Revopoint MIRACO 3D Scanner Kickstarter Sign Up

Click the link to subscribe it: Revopoint MIRACO 3D Scanner Kickstarter Sign Up

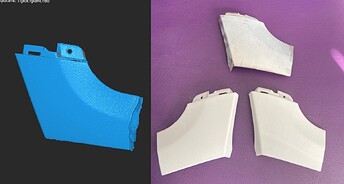

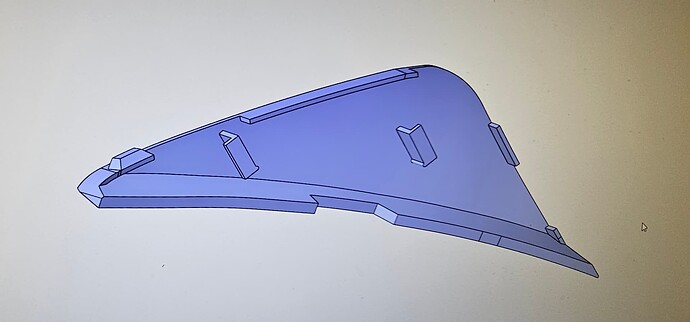

![]() Share your creations made with any Revopoint scanner in the comments section and tell us the story behind your creation.

Share your creations made with any Revopoint scanner in the comments section and tell us the story behind your creation.

Don’t miss this chance to become our beta tester and receive a free MIRACO 3D Scanner.

Remember, only one lucky winner will be selected!

![]() Recruitment period:

Recruitment period:

The recruitment runs until 10:00 PM ET (UTC -4) on Oct 12th, 2023.

![]() Winner Announcement:

Winner Announcement:

Oct 13, 2023

Applying for this opportunity means that you have agreed to our Terms and Conditions