Surgical Wire Collet.

3D scanning with Revopoint’s MIRACO of a Wire Collet used in surgery to implant steel wires into bones, allowing for the reconstruction of displaced or otherwise fractured bones that need to be secured in specific positions.

The subject has dimensions of 157x109x35mm. The scanning took place directly on the MIRACO in two separate sessions, rotating the subject 180 degrees.

Scanning was done on a manual turntable in High Precision mode, Generic Object, and Feature Tracking. Since the subject is entirely made of surgical steel, it was pre-treated with orange AESUB spray.

The files were transferred to the desktop and processed in RevoStudio5 because the two partial scans needed to be merged.

The result is excellent once again, with an extraordinarily clean model. The captured details are very high, from the very fine engravings on the wire thickness selection wheel to the details of the attachments to the drill, and even to the recesses of the covers of the rear ball bearings.

I know this subject is “a bit unique,” but I assure you that for those in the medical field, it is something well-known, and I hope it may be of interest to you.

What do you think?

Global: Revopoint MIRACO: Big and Small Object Standalone 3D Scanning

US: https://revo.ink/3SycOzd

St. Joseph’s Zeppola.

As a proud Italian, since we are approaching the feast of St. Joseph, I would like to present one of the traditions of Southern Italy, namely a typical dessert called St. Joseph’s Zeppola, which is traditionally eaten on March 19th in celebration of St. Joseph’s Day and Father’s Day, which is celebrated on the same day.

The zeppola is typically a pastry made of choux dough, fried or baked, topped with white and chocolate custard.

The scanning, done with Revopoint’s MIRACO, was carried out in a single session with the subject on turntable.

There were 3 scanner movements and one repositioning of the subject.

File processing was done on the desktop using RevoScan5 software.

The point cloud was merged in Advanced mode at 0.2mm, and the mesh was created at level 5 with a mesh size of 0.22.

The model is highly detailed, faithfully reproducing the pastry details, and the surface of the custard is absolutely perfect.

I apologize if the custard in the photos looks slightly different from the model, but repositioning the subject caused it to shift slightly…

I hope you enjoy this showcase, and I’m sorry that the model cannot convey the deliciousness of the dessert… perhaps in future updates ![]()

What do you think?

Global: Revopoint MIRACO: Big and Small Object Standalone 3D Scanning

US: https://revo.ink/3SycOzd

More showcases al the following link:

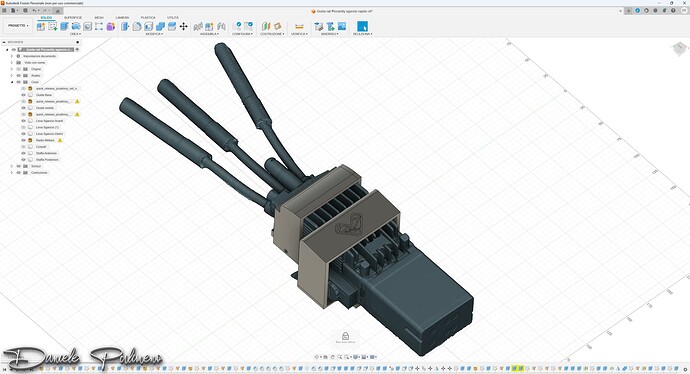

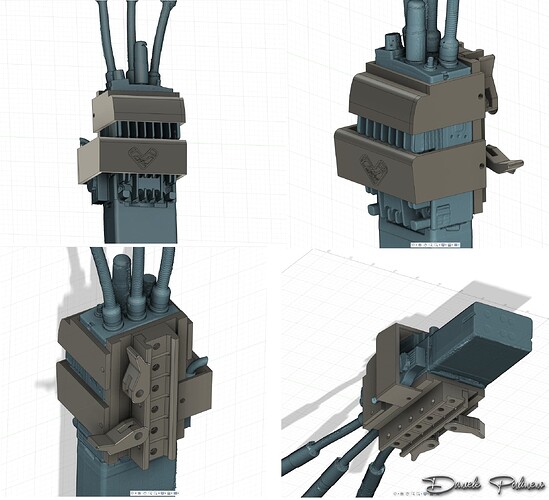

Military Radio.

3D scanning with Revopoint’s MIRACO of a Persistent Systems military radio for a client, aimed at creating quick-release attachment/detachment systems to be mounted on robots.

The subject has dimensions of 132x400x65mm.

The scanning was done in 3 steps with the radio placed on a manual turntable.

The subject was treated with a light layer of Aesub orange to facilitate scanning.

Scanning was performed in High Precision mode, feature tracking, and generic object.

The files were imported into RevoStudio5 and processed on the desktop.

The point cloud was merged in Advanced mode at 0.2mm, and the mesh was created at level 7.

The result, as always, is absolutely perfect, with highly detailed model suitable for use as a base to design the necessary parts for the project. All details, from the attachments to the screws joining the various parts, are captured perfectly.

It’s truly incredible how a scan, not intended to create an aesthetic model but only to have a model to work on in Fusion, turns out to be a perfect showcase model!

What do you think?

Soon, I’ll also share the work for which this model was needed…

Global: Revopoint MIRACO: Big and Small Object Standalone 3D Scanning

US: https://revo.ink/3SycOzd

Roronoa Zoro from One Piece.

A 3D scan of an action figure depicting Zoro, one of the protagonists of the manga One Piece, with dimensions of 167x106x84mm.

The scan was performed using the MIRACO connected to a computer in PC mode.

The scanning process was completed in a single session, with the model placed on a turntable rotating at 120 seconds per revolution. The scanner was repositioned three times, and the subject was adjusted twice. Some shots were also taken in Single Shot mode to better capture difficult-to-reach details.

The point cloud was fused in Advanced mode at 0.1mm, and the mesh was created at level 7 with a 0.14mm grid.

The model is perfect in all its parts, with incredible detail on the hands, swords, and even the small cords attached to the swords or the handkerchief tied to the character’s arm.

The model was then reprinted to scale with an almost flawless result.

Another great performance by this scanner, which continues to impress and improve thanks to the continuous and meticulous work of the entire Revopoint team!

Having a 3D scanner makes life so much easier. The MIRACO has made the process of creating specific parts for my clients much simpler and more precise. I wanted to share with you a recent project where I designed and created a quick-release system for military radios that needed to be installed on a robot. The Picatinny system mounting brackets were designed in Fusion directly onto the 3D scan of the radios and specifically tailored to be easily attached and detached from the robot. Plus, the design allows for easy battery changes without removing the radios from the brackets. Without the scanned model, I would have spent much more time achieving the same result. I hope you find this interesting!