A project I’m currently working on is requiring big 3d-printed parts to later create carbon molds. Previous tests I conducted indicated PLA+ to be the filament with least warping and shrinkage. After printing 125kg of it for the project and getting the Trackit it was finally time to put these initial findings to a test.

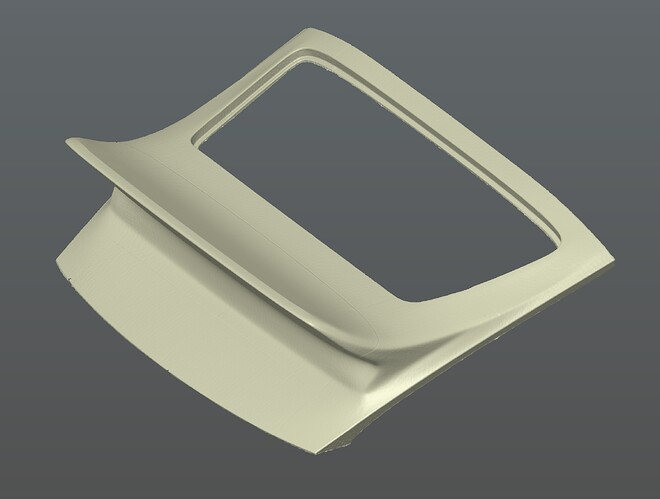

In the first picture you can see me scanning the printed tailgate with spoiler (inspired by vintage Porsche models). Scanning itself was very easy since I was able to just put the part on the table and start scanning. Only noteworthy part is the usage of an extension cable between scanner and tracker for more slack in the cable (here you can find it: PrintedForFun | Printables.com ). The slighly matte white material is optimal for scanning and produces great results.

The scan came out great and took less than five minutes to scan, post processing 3 to 4 minutes in RevoScan including fusion and meshing. Part was fused and meshed at ~1mm.

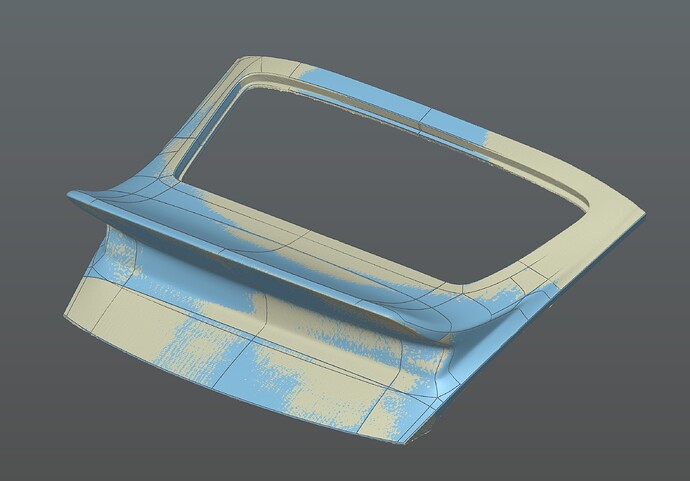

Interestingly the surface ripples you can see here are also on the printed parts. I may have pushed my K2 Plus a bit too far… Additionally you can see where the parts were glued together. The seems look worse in the scan than in real life and may be exaggerated by the shader in Quicksurface Pro. Prints were performed with an 0.8mm nozzle, 0.4mm layer-height and 45mm3/s flow-rate (comes out to ~3.5kg of PLA+ printed in 24h).

Dimensions of the part are roughly 920mm wide and 725mm deep by 275mm height. It consists of multiple prints with a max size each of 345mm cubed (printer limitations).

To allow comparison between print and CAD-model I simply imported the model form Fusion360 into Quicksurface, performed a rough alignment by picking a few common points and then used fine-align to let the software pick best fitment. CAD is blue, scan is sand colored. By first look it already looks promising with some expected sag in the thin parts.

When looking at the deviation-analysis it looks even better. The massive solid parts of the spoiler show nearly no relevant deviation (everything green is within ± 0.3mm) which is better than expected. Only parts with higher inaccuracy is the thin bridged parts and its side. Laying flat on a table some sag was expected which comes out to ~1.1mm in the middle.