Project Background

For a current project I needed to scan the 3D printed parts to compare with the CAD-model (as shown in my previous post). The project is for a custom Porsche exterior and consumed quite a lot of material with roughly 150kg printed parts which will be later manufactured from Carbon. While post-processing the scans in RevoScan I noticed the individual scans to overlap quite nicely and later decided to export them separately as meshes for further analysis in Quicksurface.

First Tests in Quicksurface

The 4 individual scans were each taken with the Trackit in tracking mode and meshed at 1.5mm. One of the first indicators of a good volumetric accuracy is the scans individual colours blending together as seen in almost all overlapping areas.

Using Quicksurface’s “Compare to other meshes” feature I can select my main mesh (the roof) and get the distance to the other scans colour-coded. Everything in green is within 0.3mm tolerance, most probed points are within 0.1mm.

Overlap at the hood is even more consistent with almost all points within 0.1mm or less. Sadly I didn’t gather enough data of the hood to fill in the gaps and get more overlap.

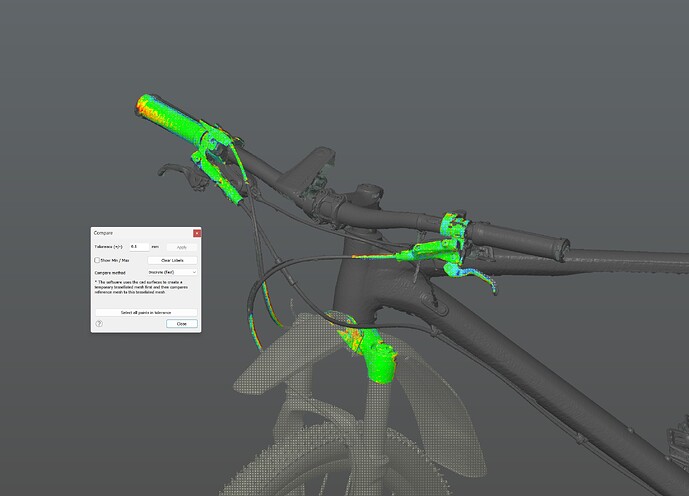

For another scan I had to make two scans of a bicycle: Whole bike excluding front wheel as first scan and front wheel including small parts of the handlebar for easier alignment. As you can see the scans aligned quite nicely and are for the most part within 0.1mm tolerance.

Explicit Testing

Setup

To get more concrete data about repeatability and volumetric accuracy I created a test scenario which involved scanning a predefined area multiple times. The only difference was the positioning of the tracker (base-station of the Trackit used to track the hand-piece).

Test Area

For testing I used the wall of my office with two paintings. The larger painting is print on canvas and the smaller one is paper behind glass.

The size of the test area is roughly 2.3-2.5m by 1.8m.

Individual Scans

Three scans with the Trackit were performed. Scans “Side 1” and “Side 2” were with the same tracker position at the side of the test area (tracker was touched in between for a powerbank change). Scan “Front” was with the tracker placed frontal to the test area. The drawing shows the setup with distances between tracker and test area:

Scan Results

The scans were taken with the Trackit prewarmed to at least 20°C in normal mode with the scanning distance set to maximum, auto exposure and a target point distance of 1mm.

Fusion and meshing was performed at 1mm with isolation and overlap detection between fusion and meshing.

I tried to scan the same area every time but unintentionally got bigger scan after scan… Poses no real issue since I only look at the overlap.

Repeatability

As a crude way of comparing repeatability I compared the scans “Side 1” and “Side 2” which were both taken from the same tracker position. The scans aligned very nicely with picking a few common points and performing fine-alignment.

For the deviation analysis I chose a tolerance value of 0.1mm which means all points with less than ± 0.1mm deviation are coloured green. As you may see almost all points are within this tolerance, most probed points are even within 0.02mm tolerance. The only real outliers lay in the only barely scanned areas at the edges where I often tilted the scanner when reaching limitations due to tracking FOV and at the small painting where reflection in the glass may have degraded the results. The areas with “worse” tolerance also show visible lines, I should have scanned these areas more thoroughly.

Conclusion - Repeatability

The repeatability between “Side 1” and “Side 2” appears to be excellent, with most deviations well below 0.05 mm across the overlapping regions. Given that the tracker was physically touched and re-powered between the two sessions, this indicates that the Trackit maintains stable repeatability. However, it’s important to note that this test only represents short-term repeatability under nearly identical environmental conditions, on a mostly planar surface, and with minimal translation between the scans. Therefore, while the results are promising, they should be considered representative only for local consistency rather than long-term or volumetric stability. A more controlled test with defined geometrical artifacts and multiple independent sessions would be needed to statistically confirm these results.

Volumetric Accuracy

An even cruder way to determine volumetric accuracy is to compare “Scan 2” and “Scan Front”. The trackers placement was rotated by 90deg relative to the scanned wall. In an ideal world I would have a nice, big, calibrated ball bar but they are prohibitively expensive.

This deviation analysis is also performed with a target tolerance of 0.1mm. Generally speaking most of the area is within the target tolerance with outliers mainly in the areas far to the side. This may be originated in too few captured point in these areas (target point distance was met while scanning). An alternative reason could be me angling the scanner flatter to the wall in order to reach further to the sides (Some plants obstructed the view on the window side and tracker could have been positioned further away). Looking at the deviation values it still is very little with the “high” outliers at roughly 0.3 to 0.4mm for a scanning area of 2.5 by 1.8m.

Conclusion - Volumetric Accuracy

For a scanned area of around 4.5 m², a maximum deviation in the range of 0.3–0.4 mm corresponds to a volumetric accuracy on the order of 1:6000 to 1:8000 relative to the measurement span. This is quite respectable for a consumer-grade optical tracking system. Nonetheless, this test setup is not sufficient to claim true volumetric accuracy. The surface used (a wall with paintings) is not a calibrated geometric reference, and any small misalignment during manual registration directly biases the results. Furthermore, since no absolute reference scale was verified after changing tracker position, the comparison mainly reflects relative shape preservation rather than global metric accuracy. Future tests should ideally involve calibrated length artifacts or fixed fiducial markers distributed in 3D space to separate tracking drift from geometric scale error.

Findings

For me there are mainly two findings to ensure high accuracy: Capture enough points to prevent streaking and try to keep the scanner as parallel as possible to the scanned surface. For my use cases the Trackit succeeded expectations (especially when thinking about the price) and with further testing, better testing equipment (hopefully I will get hands on a calibrated reference geometry) and more time I will extend the tests.

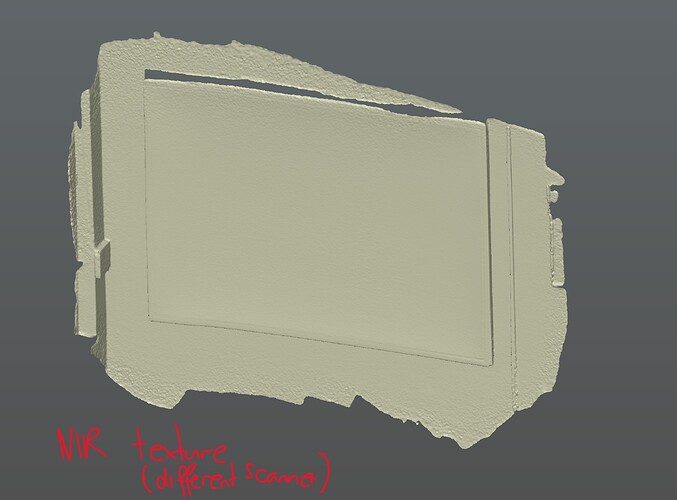

Addendum: Texture tracked NIR

Whilst scanning with the Trackit I got curious to add another test: Texture tracked NIR scan with a scanner from a different brand. I will not say which scanner since the test itself is not fair since the other scanner theoretically supports markers in NIR mode for better volumetric accuracy but I am lazy.

The scan itself instantly looks way worse since it was scanned in the scanners largest FOV mode to improve texture tracking which only worked on the painting since the wall has a homogenous colour, The edge areas of the scan look very rough and keep getting rougher the further outside.

Looking at a deviation analysis where I compared the Trackits “Side Scan 2” to the NIR scan the results look quite shocking. Declaring the Trackits scan as the absolute reference which it seems to be after the previous tests the NIR scan is significantly warped to the center with deviation in the center of 8mm and at the edges up to -6mm. This shows quite clearly: don’t trust texture tracked scans, feature tracked may bet better but was sadly not possible with the test area.

Trackit Accessories

Some of you may already be exhausted by my advocating for these designs for the Trackit but I think they greatly improve the user friendliness of the scanner: PrintedForFun | Printables.com